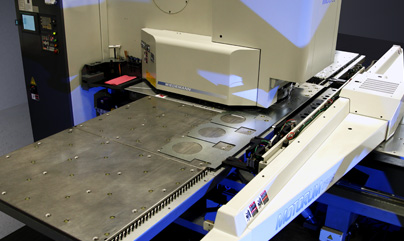

In our modern facility, we design, prototype, fabricate and offer a wide range of manufacturing services to our clients. Our capabilities include rapid prototyping, shearing, automated CNC punching, forming, bending, welding, powder coating, assembly, packaging, production integration and inspection.

Our innovative equipment including multiple turret press cells allowing for continuous production with high quantity stacking, automated panel benders, and multi-axis press brakes. These machines, along with our fully trained operators/engineers ensure smooth implementation, minimum downtime and rapid changes to design specifications.